CRVI offers a range of cutting-edge services to meet the needs of industry in industrial robotics, artificial intelligence, and computer vision.

Looking to improve your processes and product quality using robotics, computer vision, or artificial intelligence? Conducting preliminary diagnostics is the first step.

Our experts can give you the objective advice you need by analyzing your production applications and suggesting a practical approach for integrating new technology.

Not sure what kinds of technical and economic challenges may lie ahead? You need a technical and economic feasibility study.

Our impartial experts will compile all the information needed to conduct lab tests and carry out digital and economic simulations that will show whether your selected technologies are the right ones for the job.

You’ll gain a clear picture of performance, quality, and return on investment and be able to develop precise technical specifications.

And that will simplify the tendering process with equipment suppliers.

Are you experiencing technical, technological, quality, or productivity issues and need an outside perspective? Our experts can help you find the right technical solutions and suggest improvements.

Is developing technical resources a challenge for your company? You need training in robotics and/or industrial vision that’s tailored to your specific needs.

CRVI has local facilities specially designed and equipped for this. We can also train your staff on site at your plant.

Unsure of the technological challenges facing your new product or process? Our team can help by carrying out experimental development and concept validation for you in our state-of-the-art laboratories. That will save you from having to disrupt production or buy equipment that may not end up meeting your final requirements.

As part of our R&D activities and feasibility studies, our experts can transfer technology to your staff so they are fully equipped to operate the newly developed or validated technology.

Robotics

Conventional Processes

- Handling

- Pick and place

- Feeding machines

- Adhesive distribution

- Robot painting

- Multi-robot programming

- Robot welding

- Welding processes: GMAW – MCAW – FCAW – GTAW – PLASMA

Collaborative Robotics (4.0)

Mobile Robots Programming and Fleet Management Systems

Advanced and Autonomous Robots (4.0)

- Trajectory generation from 3D scans

- Increased precision

- Random bin picking

- Adaptive welding with Servo Robot camera

- Adaptive multipass welding

- Robotics expertise

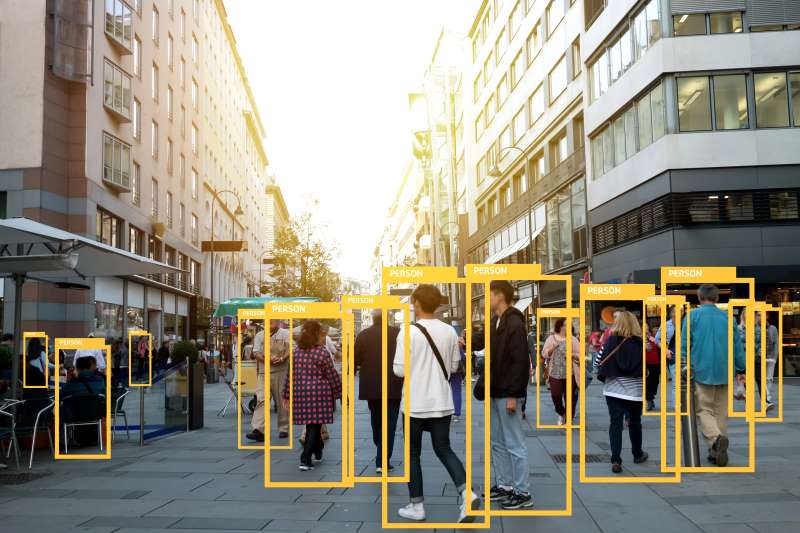

Computer Vision and AI

Artificial intelligence applied to 2D and 3D image processing

- Algorithm development

- Machine learning: Deep learning, neural networks, classification, data mining (big data)

- Optimized programming for parallel processing

Design and calibration of optical systems and lighting control

- Sensor calibration: Optical aberration correction, sensor modeling and simulation, target calibration (radiometric and geometric), SNR estimation

- Spectral analysis and infrared imaging

- Image processing: Image enhancement, noise reduction, segmentation, object detection, color correction

Fields of application:

- Artificial vision

- Defect detection

- Increased robotic precision

- Agronomy

- Wood processing

- Wind turbines

- Scene comprehension: Target classification and recognition

- Video surveillance

- Games and Simulation Software

- 3D object recognition and reconstruction

- Inspection

- Human and animal biometrics

- Plant morphology

- Metal components

- Robot trajectory generation